Fiberon - CVD

Process

-

1

Specially Diblgneci highly software CVD process like Cleavine. Corine and Seed Sewation.

-

2

Consistent Results and Reliability

-

3

Enceptional Beam Oualitv gives lowest breakages.

-

4

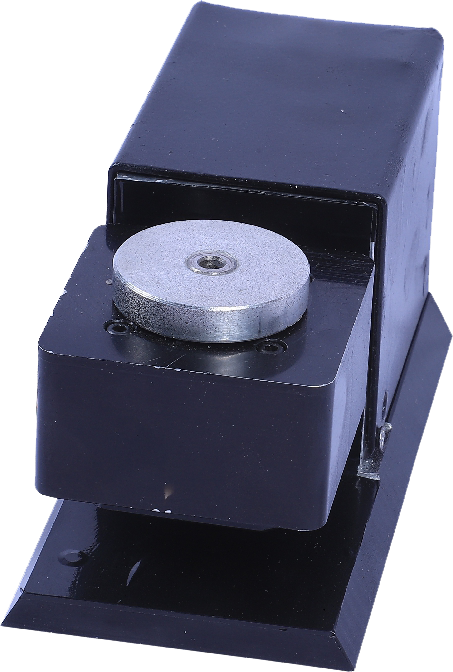

Best model In Performance Witn attractive 8 sleek tteslgn in industry.

-

5

Robust end sturdy structure for lowest vibration. minimum maintenance and high quality Output.

-

6

Industry proven Components for lone terms stability.

-

7

Na Chiller required.

-

8

Energy efficient (33% power saving).

-

9

Smallest foot pnnt (space saving).

-

Laser: PULSED FIBER LASER

-

Wavelength: 1064 nm

-

Polarization: Random

-

Beam Roundness: >90%

-

Average Power: >14 W

-

Repetition Rate: 10-14 KHz

-

Axis Travel: 130mm x 130mm x 70mm

-

Resolution: 2 Micron

-

Accuracy: 2 Micron / 25mm

-

Repeatability: 2 Micron / 25Micron Bidirection

-

Driver: AC Servo & Stepper

-

Power Requirement: 220 VAC +10%,1 Phase,50Hz

-

Power Consumption: <1.5 KVA

-

Room Temperature: 240 C - 260C

-

Length x Width x Height: 780mm x 900mm x1550mm

-

Weight: 250Kg